Condition Based Maintenance (CBM) is a maintenance strategy aimed at extending machine life, increasing productivity, and lowering your daily operating costs. Unlike periodic maintenance (PM) where services are based upon scheduled intervals, CBM relies upon actual machine health to dictate when and what maintenance is required. By considering operating environment, temperatures, and application, CBM delivers better control over the health of the machine.

CBM delivers machine performance customers have come to expect from John Deere. Although PM has proven to prevent some failures, many machines still experience premature and/or major failures. Unanticipated failures and emergency repairs have a negative effect on your uptime and don't match up with the John Deere value proposition:

- Maximum Productivity

- Maximum Uptime

- Lowest Daily Operating Costs

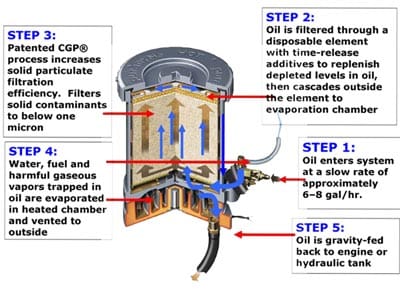

The fact is that even a small failure can lead to a catastrophic one if not addressed proactively. Monitoring machine health and controlling contamination are key to eliminating failures. In addition, extending oil and filter service internals through the use of bypass filtration, shown below, contributes to lowering machine operating cost.