Smooth and Even Feeding

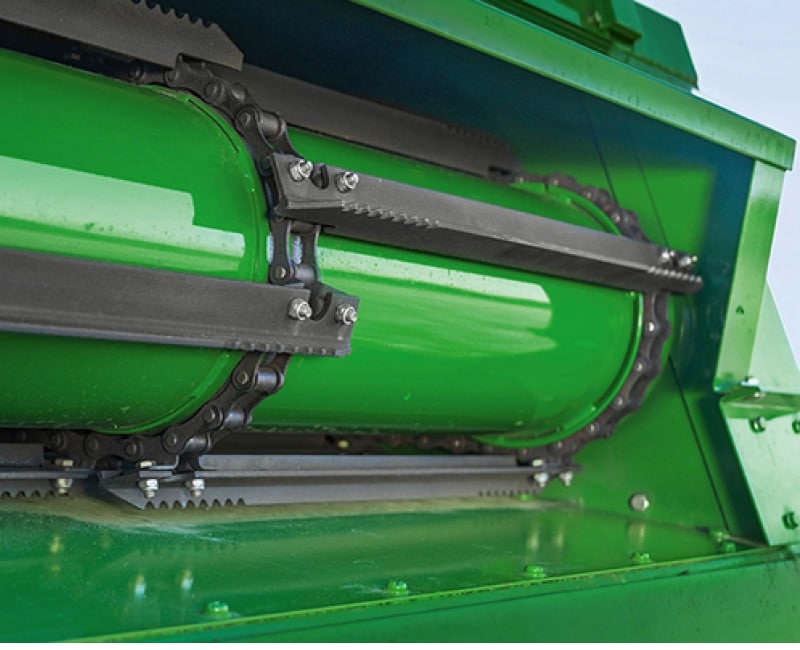

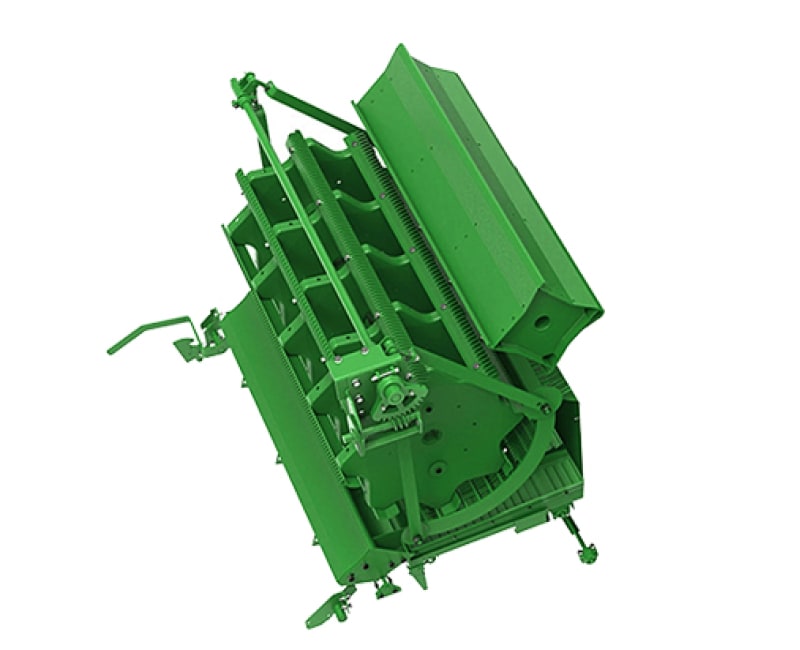

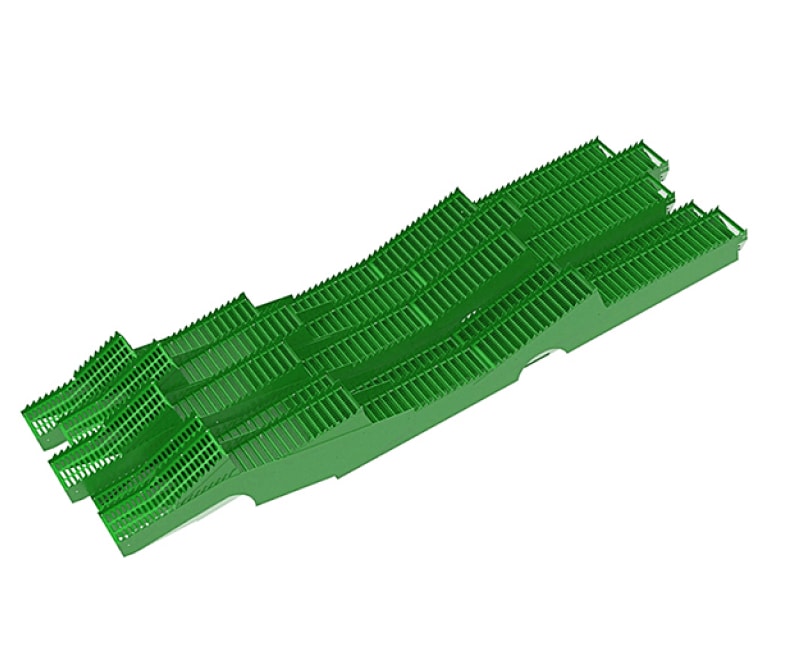

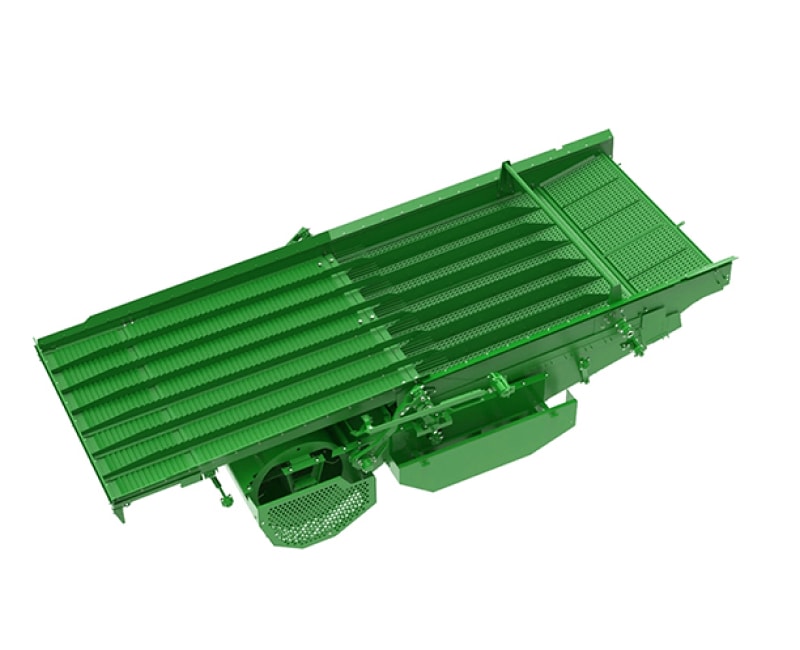

1300 mm wide feederhouse ensures smooth and even feeding in different crop conditions. The floating drum on the feederhouse provides large areas of clearance for uninterrupted high volume crop flow. The closed front drum design ensures less wrapping and higher protection against stones and other foreign objects. Stone trap protects the threshing system by effectively catching stones and is easily accessible for cleaning.

With Feederhouse Reverse feature, offered in base on all W2 400 combines, the operators can easily resolve any plugging issues from the cab thereby minimizing downtime.