Combine Advisor is a suite of technologies designed to maximize harvesting profits. The features help the operator set and optimize the S700 Combine and then automates the combine to maintain performance target as conditions change. Purchasing Combine Advisor grants access to the Integrated Combine Adjustment 2 (ICA2) application, which houses three automation technologies: HarvestSmart™ system for automation of feed rate, Active Terrain Adjustment™ (ATA) system for terrain change management, and Auto Maintain with ActiveVision™ cameras for crop condition change management.

Combine Advisor also provides easy navigation of the S700 set and optimize features: harvest settings application for initial set up and setting storage, VisionTrak system for monitoring losses and harvesting performance, and the Interactive Combine Adjustment (ICA) performance wizard for step-by-step guidance of combine setting optimization. Once John Deere Combine Advisor is set into motion, the operator will experience ease-of-use benefits coupled with increased productivity.

| Code |

Description |

| 1962 |

Combine Advisor Base features, plus ATA and ICA2. Includes ActiveVision cameras. Base features include ICA, TouchSet™ system, VisionTrak, HarvestSmart, and engine speed management. HarvestSmart and engine speed management only included with code 2020 (ProDrive™ transmission). Engine speed management only available with Final Tier 4 (FT4) engines. |

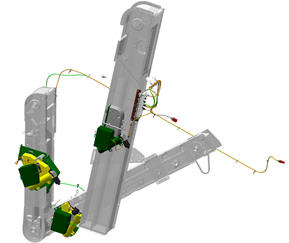

ICA2 hardware and software

Beginning in late summer/early fall, retrofit bundles for ICA2 will be available for model year 2018 and future models. The bundles include ActiveVision cameras, harnesses, Auto Maintain, and software.

Dealer installation instructions are included, as weldments and drilling are required. The process will most likely take around 10 hours of labor.

| Bundle |

Description |

| BXE11034 |

ICA2 retrofit bundle for S760 and S770 Combines Also requires BXE10948 Active Terrain Adjustment bundle if the combine is not already equipped. |

| BXE11035 |

ICA2 retrofit bundle for S780 and S790 Combines Also requires BXE10948 Active Terrain Adjustment bundle if the combine is not already equipped. |

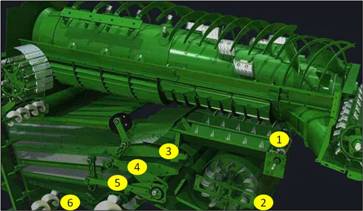

ICA2 retrofit bundle components

ICA2 retrofit bundle components

| Bundle components |

| Camera material imaging sensor |

| Drive pressure separator |

| Grain quality bracket mounting parts |

| Grain quality controller module |

| ETN Intelligent Power Management (IPM) controller software |

| ETN CABC software |

| IPM - cab wall video wiring harness |

| IPM - grain quality wiring harness |

| IPM - tailing camera wiring harness |

| IPM - rethresher wiring harness |

| IPM mounting bracket |

| Mount to elevator |

Combine Advisor video

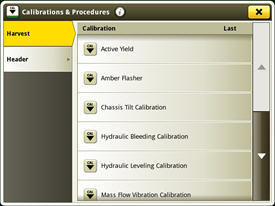

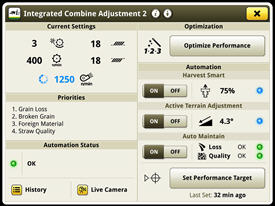

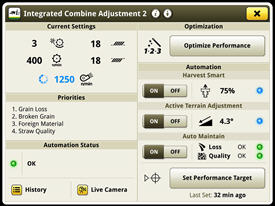

ICA2 Application

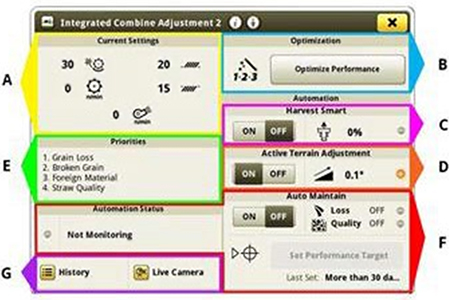

ICA2 run page

ICA2 run page

The ICA2 application provides the tools needed to set the combine to get the most out of it and automatically adjust settings to maintain optimum performance. Inside this application on the 4600 CommandCenter™ display, the operator will find many tools including easy-to-adjust current machine settings, priority setting for automation guidance, application status indicators, automation activity history overviews, and live grain analysis camera feeds.

Additionally, the operator can access the Optimize Performance wizard, activate three automation technologies, and set the performance targets the machine will automatically adjust to maintain.

Feature benefits:

- Efficient combine operation with a one-page application for animation technologies

- Improved combine settings management with settings, priorities, and status information all on one reference page

- Reduced operator training and efficient, easy control of harvest settings through an intuitive run page and user interface

Functionality:

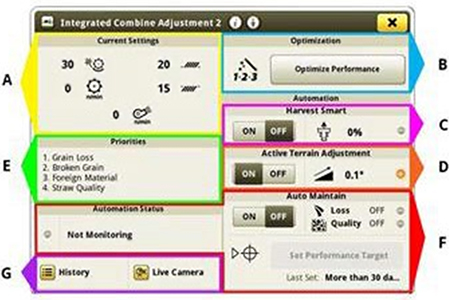

ICA2 run page

ICA2 run page

The ICA2 application page gives the operator seamless access to many features.

- Section A (yellow highlight): takes the operator to the current settings for concave clearance, rotor speed, fan speed, chaffer clearance, and sieve clearance, giving quick access to critical combine adjustments.

- Section B (blue highlight): the Optimize Performance button uses a wizard to help the operator optimize combine performance.

- Section C (pink highlight): the HarvestSmart system automates ground speed control during harvest to maintain a constant crop load.

- Section D (orange highlight): the Active Terrain Adjustment system increases productivity and reduces tailings volume when harvesting up and down hills.

- Section E (green highlight): indicates the operator’s priorities for automation.

- Section F (red highlight): Auto Maintain monitors the combine and makes adjustments to maintain the performance at the operator-set performance target.

- Section G (purple highlight): Auto Maintain also uses the buttons in section G to allow a glimpse into live views of the clean grain and tailings elevators and allows operators to use an analyzer function to see what Auto Maintain is seeing.

|

- The automation features are dependent on the performance target sets. There are two ways a grower achieves an optimal target:

- Combine optimization with the aid of ICA2 Optimize Performance wizard

- Dealer support via a combine optimization value added service

- Combine Advisor has been available as a factory-installed option since model year 2018 combines.

- Auto Maintain is compatible for corn, soybeans, wheat, canola, and barley.

- HarvestSmart is included only with ProDrive transmission code 2020.

- Active Terrain Adjustment is an optional feature that is orderable with codes 1961 or 1962.

|

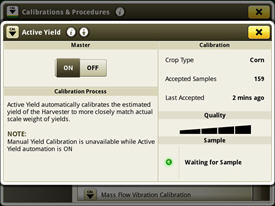

Auto Maintain

Auto Maintain with ActiveVision cameras is technology that works by automatically adjusting S700 Combine settings to maintain the ideal targeted performance. When harvesting corn, soybeans, wheat, canola, or barley, the combine will maintain the performance of everything from grain loss and grain quality to foreign material in the grain tank. The ActiveVision cameras, along with grain loss monitors, are specifically designed to identify the impact of crop condition changes and adjust the combine to maintain target performance, allowing the operator to focus on other challenges of harvest.

Feature benefits:

- Simply harvest by automating the critical workload of constantly managing combine settings when conditions change

- Increase productivity by allowing ActiveVision cameras to identify and address tough-to-spot problems such as cracked grain

- Provides flexibility in planning overall business and increases the productivity of the combine independent of operator experience

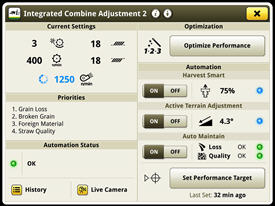

ICA2 run page

ICA2 run page

Functionality

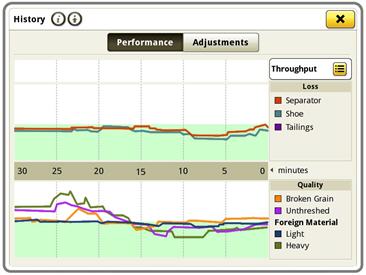

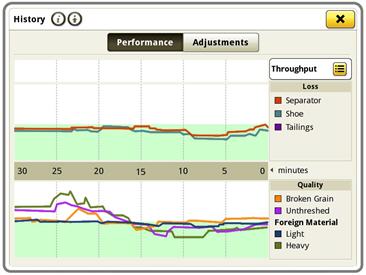

Auto Maintain looks at the level at which the combine is performing, sets that as the goal, and automates combine settings to continually hit the target performance goal over and over again. Auto Maintain uses existing sensor inputs along with the ActiveVision cameras to make decisions for accurate combine adjustments. It does not use grain moisture as an input, however. Auto Maintain is able to hit the target goal by automatically making adjustments to the threshing speed, concave clearance, chaffer clearance, sieve clearance, and fan speed. The ActiveVision cameras have been trained by university experts to analyze the clean grain and tailings material and input that analysis into the Auto Maintain system. Auto Maintain will show the operator how it has been performing with a constantly updating historical graph of losses, grain quality, and foreign material in the clean grain. The green-shaded area below indicates the performance targets set. The colored lines show the ongoing levels of losses and quality. For example, the green, purple, and orange lines below show a period of time outside of the green-shaded acceptable area. Auto Maintain with ActiveVision cameras recognizes this and the Combine Advisor package makes the appropriate adjustments to meet the set targets.

Historical Auto Maintain performance graph

Historical Auto Maintain performance graph

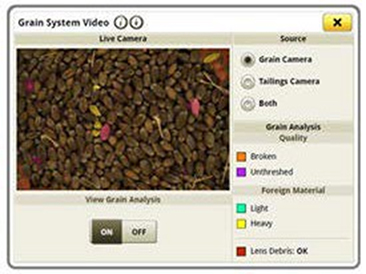

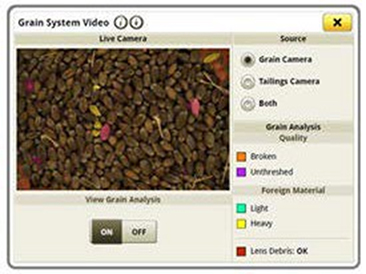

The ActiveVision cameras can detect broken and unthreshed grain. The cameras will also detect lightweight and heavy foreign material to make the appropriate combine changes. If the operator wants to see the grain as well, the system will highlight the broken and unthreshed grain to make it easier to analyze. The live view and historical graphs update constantly and the cameras can even tell the operator if there is debris on the lens.

Grain analysis live view

Grain analysis live view

|

Combine Advisor with Auto Maintain is available as a factory-installed option on combines since model year 2018. Auto Maintain is compatible in corn, soybeans, wheat, canola, and barley. |

Additional Combine Advisor features: